| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | RLD Tools |

| Model Number : | HRC55 |

| Price : | Negotiable for Aluminum End Mill |

| Payment Terms : | T/T/PayPal/Credit Card |

| Supply Ability : | 100000pcs/month |

| Delivery Time : | 5-8 work days |

| Certification : | ISO |

RLD End Mill Catalog in English.pdf

Material: Carbide (tungsten steel)

Coating: DLC coating

Spiral Angle: 45 Degree

Flute: 3 Flutes

For: Aircraft Alumunium Alloy (Al5052,6061,7075), cooper electrode

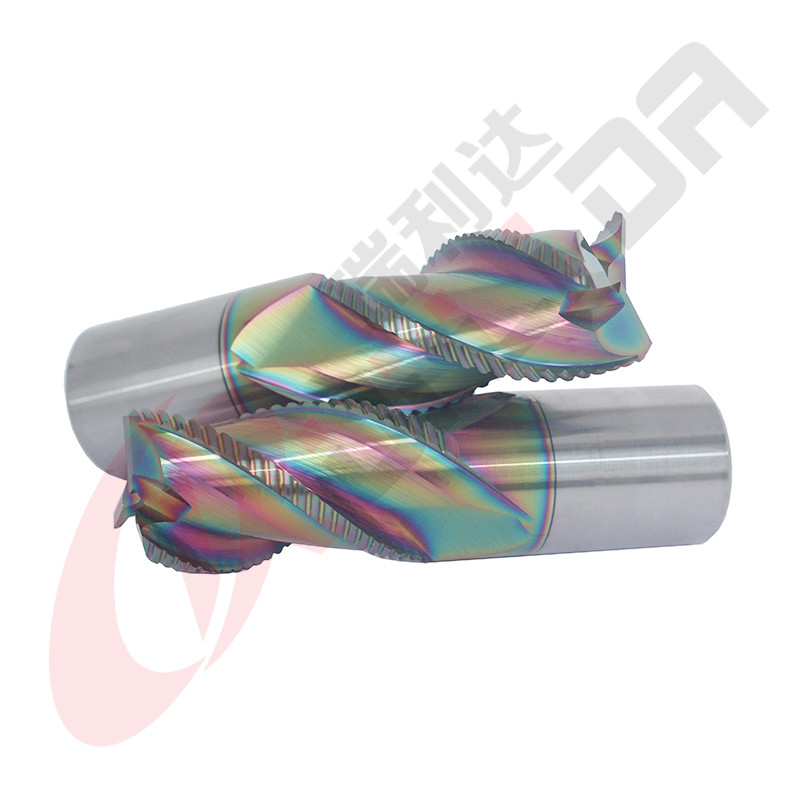

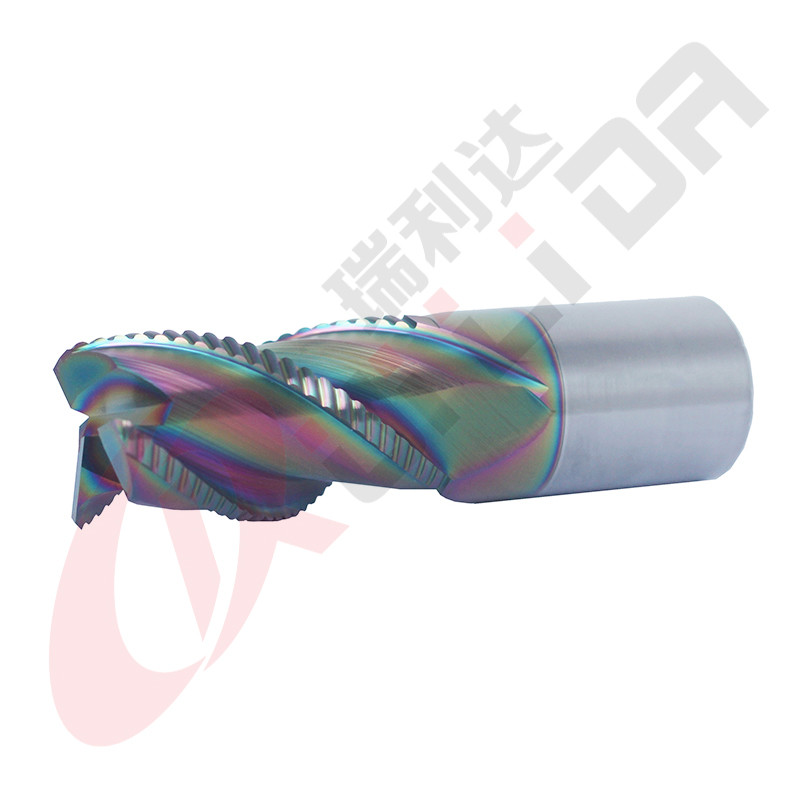

| Product name | RLD 25mm 1" 3 Flutes Roughing End Mill for Aluminium Carbide CNC Rough Milling Cutters |

| Size | 25mm/ 1" |

| Suitable for | Aluminum, Copper, brass, etc |

| Feature | Can be used for roughing and finishing |

| Flute Number | 3 |

| Coating | DLC |

| Helix angle | 45° |

| Co | 12% |

| HRA | 92.8 |

| TRS Min(N/mm²) | 4000 |

| Processing machine | ANCA/ |

Carbide Raw Material Introduction

| End mill grade | Carbide rod | Grain size | HRA | Application |

| HRC50 | YG10X | 0.6μm | 91.8 | Aluminum, iron, low alloy steel, general steel under hardness HRC45 |

| HRC55 | WF25 | 0.6μm | 92.2 | Cast Iron, Alloy Steel, General steel under hardness HRC50 |

| HRC60 | GU25UF | 0.4μm | 92.5 | Super Alloy Steel, Stainless Steel, Titanium, Inconel, Hardened Steel under hardness HRC55 |

| HRC65 | GU092 | 0.2μm | 93.5 | Alloy Steel, Hardened Steel under hardness HRC62 |

What is DLC coating?

DLC (Diamond like Carbon) has great hardness and lubricity. DLC is a very popular coating for machining aluminum, graphite,

composites and carbon fiber. In aluminum this coating is ideal for high production light finishing applications such as finish profiling

and circle milling where holding a size and finish is critical.

How to Choose an end mill for Aluminium?

If you ask 5 axis CNC machinists the same question, you’re bound to get several answers. But that doesn’t mean they're indecisive, just there are many different ways to perform any given CNC operation. Here are a few things to keep your eyes on when buying end mills.

1. Carbide

There are many different grades of carbide rods.

It's difficult to check the quality according to HRC50, HRC55, HRC60, HRC65...

Because the so-called HRC50/HRC55 depends on different suppliers.

For the same HRC55 end mill, the quality from different companies many has a huge difference.

So, when we purchase the carbide end mills.

We'd better ask the supplier end mill is made of what kind of carbide rod?

The percentage of Co, HRA, Grain size...

2. Grinding machine

Usually, the precision of the end mills made of world famous brand grinding machines is better.

This is also very important when you buy the carbide round cutters.

3. Coating

Aluminum is soft when compared to other metals. This means chips can clog up the flutes of your CNC tooling, especially with deep or plunging cuts. Coatings for end mills can help alleviate the challenges that sticky aluminum can create. The newly developed DLC coating with rainbow color is suitable for soft materials like aluminum, brass, wood, etc.

4. Number of flutes

This is arguably the most important feature to consider when choosing an end mill for CNC machined aluminum. Again, aluminum is gummy and soft, which means it tends to stick in the flutes of your CNC mill. While coatings can help alleviate this issue, if you’re using a 4- or 5-flute end mill to cut aluminum, even the best coatings may not help. One of the main goals of flutes when cutting aluminum is to clear CNC machined chips. While having fewer flutes makes your tool less rigid, it also allows for more efficient movement of those chips. If you don’t get chips out of there, you risk ruining your surface finish, by re-cutting chips, or worse, destroying your end mill by friction welding the chips right to your cutter - every CNC machine owners worse nightmare! Your best bet for an end mill in aluminum is two or three flutes.

This 3 Flutes Roughing Aluminum End Mill with Coarse Pitch can help you make the machining for aluminum easier and more convenient.

|